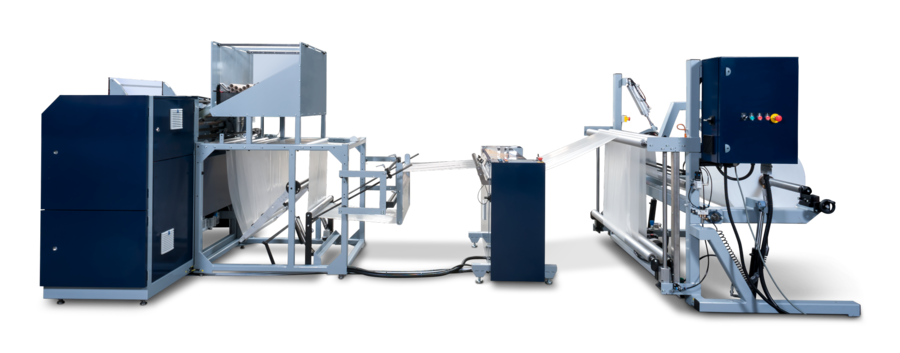

Perforator

The perforator is perfect for production of special film at high-speed, where only perforating is needed. You can produce e.g. table covers, drop cloths and cover foil on rolls. The products can be wound on cores or coreless. The perforator is a stand-alone module and can be placed in-line with an extruder, together with a bag making machine, or only with a winder.

Do you need an expert?

Find your Roll-o-Matic representative in your country

Performance

Max. film speed 250 m/min

Max. cycles/min 600

Technical Data

| IP 900 | IP 1700 | |

|---|---|---|

| Max. film width | 900 mm 35.4 in | 1700 mm 70 in |

| Min. perforating distance | 300 mm 11.8 in | 400 mm 15.7 in |

| Min. film speed | 250 m/min 820 ft/min | 130 m/min 430 ft/min |

| Max cycles | 600/min | 300/min |

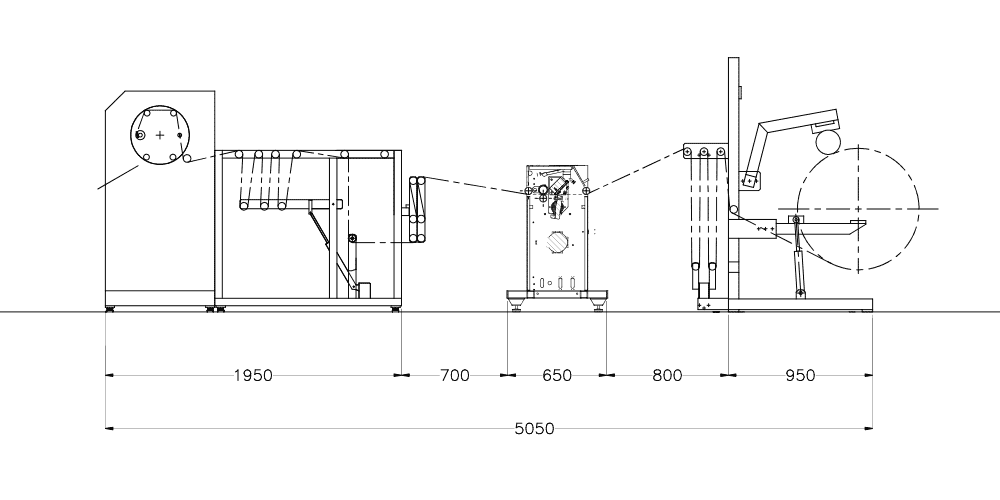

Technical Drawing

Watch the video about Perforator

Your content goes here. Edit or remove this text inline or in the module Content settings. You can also style every aspect of this content in the module Design settings and even apply custom CSS to this text in the module Advanced settings.

You will find us at the most important fairs of the plastics industry